Tech

Dignotech: The Silent Revolution Transforming Healthcare with Humanity

What Is Dignotech? (And Why Should You Care?)

Dignotech isn’t a single gadget or app. It’s a philosophy. Think of it as a bridge between cold, clinical data and warm, human-centric care. From wearables that predict seizures without alarms to AI-driven platforms that let dementia patients communicate through music, Dignotech solutions share one goal: preserving dignity while saving lives.

The Pillars of Dignotech

- Invisibility: Devices blend into daily life (no bulky hospital gear).

- Prevention: Catches issues before they escalate.

- Empowerment: Users control their data and care.

- Accessibility: Affordable, intuitive, and inclusive.

Why Dignotech Is Outpacing Traditional Healthcare

Traditional healthcare often treats patients as case numbers. Dignotech sees them as people. Here’s how they stack up:

| Aspect | Traditional Healthcare | Dignotech |

|---|---|---|

| Monitoring | Reactive (ER visits, late-stage) | Proactive (real-time alerts) |

| Privacy | Shared charts, exposed data | Encrypted, user-controlled access |

| Cost | High (hospital stays, procedures) | Lower (preventative care) |

| User Experience | Intimidating, impersonal | Calm, empowering |

Infographic: A timeline showing how Dignotech reduces hospital readmissions by 40% through early intervention.

Dignotech in Action: Stories That Stick

Case Study 1: HealthGuard’s Fall-Detection Pendant

Startup HealthGuard created a pendant that uses motion sensors and AI to detect falls in elderly users. Unlike traditional alert systems, it doesn’t require pressing a button—ideal for post-fall disorientation. Result? A 62% drop in prolonged floor waits in trials.

Case Study 2: MelodyMind for Dementia Care

MelodyMind, a Dignotech platform, uses AI to curate music playlists that trigger memories in dementia patients. One user, Frank, hadn’t spoken in months—until he hummed along to Elvis.

How to Choose a Dignotech Device (Without Getting Lost in Tech Jargon)

Not all devices are created equal. Here’s your cheat sheet:

| Factor | What to Ask |

|---|---|

| Data Control | “Can I delete my data permanently?” |

| Usability | “Does my tech-averse mom understand it?” |

| Battery Life | “Will it die mid-hike?” |

| Integration | “Does it sync with my existing health apps?” |

Pro Tip: Look for FDA clearance or CE marks—it’s a baseline for safety.

YOU MAY ALSO LIKE:

3473920893: Learn Benefits, Applications & Future Trends

The Future of Dignotech: 3 Predictions You’ll Want to Bookmark

- AI Companions: Chatbots that don’t just remind you to take pills but sense loneliness.

- Skin Sensors: Tattoo-like monitors that track glucose without needles.

- Global Equity: Startups like Nairobi’s Uzima Health bringing Dignotech to low-income regions.

FAQs:

Q: Is Dignotech covered by insurance?

A: Increasingly, yes! Medicare now reimburses for some FDA-approved wearables.

Q: How secure is my health data?

A: Reputable brands use military-grade encryption. Always check their privacy policy.

Q: Can Dignotech replace doctors?

A: It’s a sidekick, not a replacement. Think of it as your 24/7 health guardian.

Q: What if I’m not tech-savvy?

A: Design is key. Seek devices with one-touch interfaces or voice commands.

Q: Are there options for children?

A: Absolutely! Asthma-monitoring bracelets and ADHD focus tools are rising stars.

Tech

Heavy-Duty Mobility Solutions for Industrial Efficiency

Industrial operations rely heavily on equipment and machinery that can withstand demanding conditions while maintaining smooth and efficient workflows. One often overlooked factor in achieving operational efficiency is mobility—how equipment moves, adapts, and absorbs the stresses of daily use. Heavy-duty mobility solutions are designed to support substantial loads while minimizing disruptions caused by uneven surfaces, vibrations, and repetitive motion. Incorporating small shock absorbing casters into industrial carts, platforms, and transport systems can significantly enhance stability and reduce wear and tear, creating a safer and more reliable work environment.

These solutions are particularly valuable in facilities where frequent relocation of machinery or materials is required. By combining robust construction with features like shock absorption, industrial mobility systems help maintain productivity, reduce downtime, and extend the lifespan of equipment. Thoughtful mobility design ensures that operational flow remains uninterrupted, supporting overall efficiency and creating a more ergonomic workspace for employees handling heavy loads.

Advancements in Caster Technology

Recent years have seen a significant leap forward in caster engineering, specifically tailored to meet the needs of heavy-duty applications. Notably, extra-heavy-duty dual-wheel casters are now revolutionizing how plants move their heaviest and most valuable assets. Built for exceptional load capacities, these casters can withstand rigorous industrial use without succumbing to deformation or performance fatigue. Their dual-wheel design distributes weight more effectively, reducing stress on floors and enhancing both maneuverability and long-term durability.

Shock-absorbing mechanisms within modern casters not only protect delicate loads but also contribute to reduced noise and smoother transport. These improvements have enabled facilities to expand their capabilities, allowing them to confidently move precision equipment across varied terrains and tight spaces.

Automated Carousel Systems

Material handling is undergoing a digital revolution, with automated carousel systems at its heart. These systems use vertical or horizontal carousels to optimize space, sort inventory quickly, and automate the movement of parts and equipment. Automating these workflows not only reduces labor costs but also minimizes picking errors and eliminates unnecessary storage space, thereby freeing up valuable floor space for other activities.

Facilities without automation often grapple with workflow interruptions due to manual searching, misplaced goods, or inefficient storage. In contrast, automated carousel systems bring materials directly to workers, improving picking precision while drastically reducing walk time and fatigue.

Digital Transformation in Heavy Equipment

The mobility of heavy equipment is now being redefined not just by mechanical solutions, but also by digital innovation. Connected sensors and software-driven diagnostics empower real-time equipment and asset tracking, allowing teams to anticipate maintenance needs and prevent costly, unexpected breakdowns.

The Role of Digital Twins

One of the most impactful advancements is the adoption of digital twins—data-driven virtual representations of physical machinery. These models are used to simulate, test, and continuously improve processes without interrupting production lines physically. By proactively identifying performance bottlenecks or potential failures, companies can react swiftly and optimize their layouts and workflows to improve efficiency. As businesses leverage these technologies, they not only gain visibility but also actionable insights for continual improvement and cost reduction.

Sustainable Mobility Solutions

With sustainability goals rising to the forefront, eco-friendly mobility solutions are quickly becoming the industry standard. Electrified tuggers, battery-powered loaders, and hydrogen-powered vehicles offer high torque for moving large loads, while also producing far lower carbon emissions compared to their diesel or gasoline-powered predecessors. These systems benefit both the environment and plant economics by reducing fuel and maintenance costs while ensuring compliance with tightening regulatory requirements.

In sustainable operations, the use of recyclable or renewable materials in caster manufacturing, as well as the adoption of low-resistance wheels, is also gaining ground, providing another layer of efficiency by minimizing energy consumption. Beyond the direct savings, sustainable initiatives also help companies attract investment and meet the increasing expectations of eco-conscious stakeholders.

Challenges and Considerations

Transitioning to next-generation mobility systems presents challenges. Initial capital investment can be significant, and staff may require specialized training to adapt to new equipment or automation platforms. Integrating new technologies into legacy systems sometimes necessitates temporary disruptions or phased implementations. Organizations should conduct thorough assessments, pilot projects, and vendor consultations to understand both the short-term impacts and the long-term efficiency gains of such upgrades.

Conclusion

As industrial operations become increasingly complex and competitive, the importance of robust, adaptable mobility solutions cannot be overstated. With advancements in caster technology, the adoption of automated systems, the rise of digital tools, and an urgent shift toward sustainability, manufacturers can achieve safer, smarter, and more sustainable operations. Investing in these innovations not only reduces downtime and operational risk but also positions organizations at the forefront of industrial efficiency and resilience for years to come.

Tech

Innovative Uses for Paddle Blenders in Modern Manufacturing

Introduction

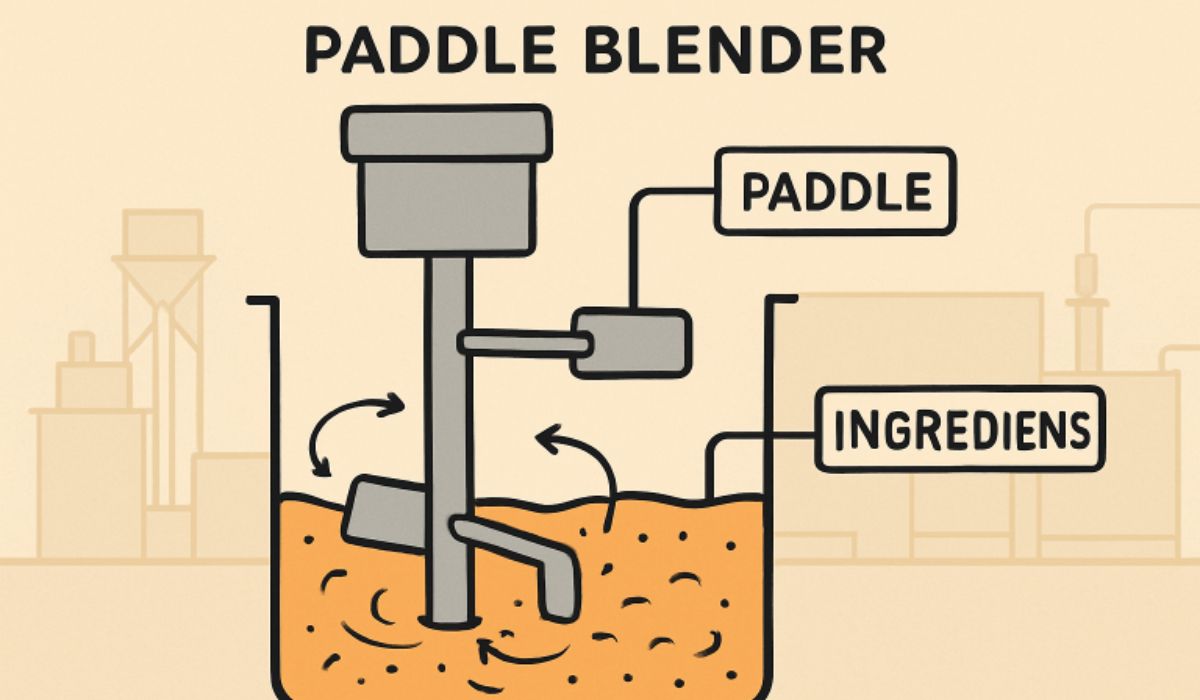

In today’s fast-evolving manufacturing landscape, paddle blenders are a cornerstone of achieving uniform, gentle mixing of various materials. Featuring a rotating shaft with multiple paddles, these machines are engineered to blend ingredients efficiently without damaging fragile or sensitive components.

Traditional high-shear mixers may not suit all products, especially those that require integrity, texture, and particle-size consistency to be maintained. Paddle blenders’ unique mechanical action makes them the solution of choice for manufacturers seeking to optimize results and protect their materials’ essential qualities.

From food to pharmaceuticals and chemicals, manufacturers are rethinking their processes and upgrading to paddle blenders for improved batch homogeneity and operational efficiency. Their versatility spans dry and wet mixing, as well as the integration of minor ingredients, which is essential for achieving specific product characteristics and standards.

As product innovation and consumer demands surge, so does the need for reliable, scalable blending technologies. Paddle blenders are increasingly part of industry conversations due to their ability to balance speed, precision, and safety.

Paddle Blenders in Food Processing

Quality, consistency, and efficiency are the benchmarks of modern food manufacturing. Paddle blenders are the backbone of operations that require even mixing of dry powders, spices, and fragile ingredient blends without degrading sensitive aromas or textures. Their gentle motion and precise control are crucial for products where uniformity directly impacts flavor and safety. As highlighted in “Mixers and Blenders: Food Safety in the Mix” from The National Provisioner, modern mixers are increasingly designed with sanitary features to minimize contamination risks, ensuring product quality and safety throughout the production process. Investing in high-quality blending equipment not only improves operational efficiency but also reinforces consumer trust in the final product. Continuous monitoring and maintenance of these machines further safeguard both consistency and compliance with industry standards.

Consistency in Blending

Paddle blenders work exceptionally well with composite mixes such as seasoning blends, granolas, nutraceutical powders, and bakery pre-mixes. The design ensures that all components are evenly distributed, ensuring each batch maintains a predictable, repeatable flavor. When liquid components are introduced (such as in marinades or oil blends), paddle blenders facilitate even coating without creating hot spots or clumps.

Meeting Regulatory and Consumer Standards

With increasing scrutiny from regulatory agencies and ever-savvy consumers, food manufacturers depend on paddle blenders to deliver traceable consistency and safety in their final products. This role has become even more critical as clean-label trends and allergen management protocols become standard practice in food processing facilities.

Applications in Pharmaceuticals

The pharmaceutical industry sets the bar high for quality and precision. For solid dosage forms such as tablets and capsules, achieving uniform blends of active pharmaceutical ingredients (APIs) and excipients is non-negotiable. Paddle blenders provide solution-driven answers to blending challenges in this regulated sector.

Uniformity Without Degradation

Unlike more aggressive mixing methods, paddle blenders avoid damaging delicate drug components. Their gentle tumbling action enables homogeneous mixing of granules and powders, ensuring each dose contains the correct API concentration.

Reduced Cross-Contamination Risks

Easy-to-clean designs and precise control mechanisms help manufacturers manage risk and streamline cleaning validation, a key consideration for multi-product pharmaceutical facilities engaged in batch production.

Chemical Industry Uses

The chemical sector relies on robust, versatile equipment to handle abrasive, viscous, or highly reactive materials. Paddle blenders, known for their structural strength, play a critical role here, offering flexibility in mixing slurries, pastes, powders, and even fibrous substances.

Adapting to Diverse Material Needs

From detergents and catalysts to rubber-based compounds and specialty chemicals, paddle blenders can blend ingredients prone to segregation or require liquid addition for optimal reaction. Their design reduces dead zones, improves cycle times, and enhances batch-to-batch consistency. Some models even support vacuum or pressure mixing, expanding their usability for complex chemical processes.

Facilitating Process Scale-Up

For manufacturers moving from pilot to full-scale production, paddle blenders offer the scalability and documentation required for industrial processes, making them a trusted addition to large-scale chemical manufacturing plants.

Technological Advancements

Ongoing R&D has led to numerous innovations that enhance the value of paddle blenders in manufacturing. Fluidizing paddle blenders, for instance, offer a faster, more uniform mix thanks to angled paddles that aerate and mobilize materials, resulting in shorter blending cycles.

Smart Controls and Data Integration

Integration with automated plant controls and sensors enables real-time monitoring of mixing cycles and temperatures, and batch tracking for complete traceability. These upgrades help manufacturers meet strict quality assurance requirements and respond more agilely to production changes.

Sustainability in Manufacturing

Energy-efficient motors, advanced seals to reduce emissions, and hygienic designs with minimal product residue address sustainability goals and reduce cleaning downtime—key advantages in a climate of rising compliance costs and environmental awareness.

Best Practices for Implementation

- Material Compatibility: Ensure all wetted parts are constructed from materials that are corrosion-, abrasion-, and chemical-resistant. This consideration is vital for product integrity and food/pharma safety.

- Regular Maintenance: Scheduled preventive maintenance (including inspection, lubrication, and periodic seal/gasket replacement) greatly extends service life and minimizes costly downtime.

- Operator Training: Invest in hands-on operator training to build in-house expertise, improve troubleshooting speed, and mitigate safety risks associated with machinery misuse.

Conclusion

Paddle blenders have evolved into indispensable mixing systems that support quality, efficiency, and safety requirements across food, pharmaceutical, and chemical industries. By embracing the latest technological advancements and following proven implementation strategies, manufacturers can future-proof production and consistently meet rising market demands. Leveraging the versatility and reliability of paddle blenders ensures that every blend—no matter how complex or delicate—meets the highest industry standards.

YOU MAY ALSO LIKE: The Importance of Reliable Raw Material Procurement in Brick Manufacturing

Tech

Pasonet: The Tech Behind Japan’s Smart Hotel Rooms

Have you ever walked into a hotel room where the lights, temperature, and entertainment seemed to anticipate your every need? Where one sleek panel by the bed replaced a cluttered nightstand of remotes and switches? Behind that seamless, almost intuitive experience, there’s often a specialized technology partner pulling the strings. In Japan’s high-stakes hospitality world, one name consistently powers these invisible journeys: Pasonet.

Forget the idea of a simple electronics supplier. We’re talking about the architect of the room’s ambient intelligence.

Beyond the Remote: What Exactly is Pasonet?

So, let’s demystify it. Pasonet isn’t a gadget; it’s a hospitality technology partner. They design and implement integrated multimedia and guest-room control solutions. In plain English? They provide the tech that lets a guest control their entire environment from one interface, and lets management orchestrate the atmosphere of an entire property from a central dashboard. They’re the reason a room can transform from a bright, energetic workspace to a dimly-lit, cinematic sanctuary with a single touch.

The Pasonet Toolbox: Solutions That Redefine a Guest Stay

Imagine Pasonet as the central nervous system for a hotel room. The bedside panel is the brain stem (handing over vital, immediate control to the guest), the customizable LED lighting is the mood-regulating limbic system, and the property-wide network is the spinal cord, carrying signals flawlessly to every corner.

Their toolkit typically includes:

- Intelligent Bedside Control Panels: The guest’s command center for lights, AC, TV, curtains, and more.

- Customizable LED Lighting Schemes: Pre-set scenes like “Welcome,” “Relax,” or “Reading” that change the room’s personality.

- Integrated Karaoke & Entertainment Systems: A nod to local preferences, seamlessly blending into the room’s ecosystem.

- Property-Wide Central Management Software: The brain for hotel staff, enabling remote control, energy management, and troubleshooting.

How Pasonet Works in Practice: The Silent Symphony

Consider a guest checking in. As they receive their key card, the front desk can trigger the “Welcome” scene in their room. They enter to find lights gently illuminated, the curtain open to a view, and a comfortable temperature set. All through centralized room management systems. Later, they use the intuitive panel to lower the lights and cue up a movie—a smooth experience powered by in-room automation.

Why Japanese Hotels Trust a Specialist: The Pasonet Advantage

You might wonder, why choose a specialist over a global tech giant? The answer is depth, not just breadth. Pasonet’s deep roots in Japan mean their solutions are crafted for local nuances—from regulatory standards to the specific expectation for integrated entertainment. This Japan hotel tech expertise ensures reliability and a guest experience that feels instinctively correct.

Furthermore, as a hotel IT integration specialist, a huge part of their value is ensuring their system speaks fluently with your existing Property Management System (PMS) and other software, creating a unified tech stack rather than another digital silo.

Dispelling the Myths: What Pasonet Is Not

Let’s clear the air. You might think, “This sounds complex and only for new builds.” In reality, many solutions are designed for retrofitting. And while the benefits for guest satisfaction are obvious, the central management software drives hard operational wins: slashing energy costs, streamlining maintenance, and providing data on how rooms are actually used.

The Future of Room Control: Where Does a Vendor Like Pasonet Go Next?

The journey is toward even greater personalization and anticipation. Think of rooms that adjust to a repeat guest’s documented preferences automatically, or systems that integrate with guest smartphones for a truly keyless, tailored stay. The line between a hotel room and a personalized digital sanctuary is blurring.

3 Takeaways for Hospitality Operators Today:

- Audit for Fragmentation: Look at your current room tech. How many different remotes and interfaces is a guest facing?

- Prioritize the Control Interface: That bedside panel is a primary touchpoint. Is it intuitive, powerful, and reflective of your brand?

- Evaluate Specialists: Consider the long-term value of a dedicated partner like Pasonet versus a patchwork of general suppliers.

As the expectations for a seamless, personalized stay become the global standard, the question isn’t if you’ll adopt integrated room control, but which partner will help you execute it flawlessly.

You May Also Like: What is Milyom? The New Branding Wave

FAQs

Is Pasonet only for large, luxury hotels in Japan?

While they have a strong presence in the high-end segment, their scalable solutions are designed for various property sizes, from boutique business hotels to sprawling resorts, that seek integrated control.

What sets Pasonet apart from global smart room companies?

Their deep specialization in the Japanese market. This means solutions are tailored to local guest expectations, building regulations, service styles, and even specific entertainment preferences like integrated karaoke systems.

Does implementing a system require a full room renovation?

Not necessarily. Many solutions are designed for retrofitting existing rooms. However, for the most seamless and optimal integration, installation is often planned during scheduled refurbishments.

Can Pasonet’s system integrate with other hotel software (PMS, CRM)?

Absolutely. As a specialist vendor, ensuring their central management software communicates effectively with a hotel’s existing tech stack (PMS, CRM, energy management) is a core part of their service and value proposition.

Is the primary benefit just guest satisfaction?

While that’s a major and direct outcome, the central management aspect is a powerhouse for operational efficiency, measurable energy savings, preventative maintenance, and gaining valuable data insights on room usage patterns.

-

Home Improvement12 months ago

Home Improvement12 months agoEasy Ways to Clean and Maintain Your Foam Play Mat

-

Celebrity1 year ago

Celebrity1 year agoWho Is Andrew Santino Wife? The Full Story

-

Tech1 year ago

Tech1 year agoExplore iZoneMedia360 .Com Features & Benefits

-

Entertainment1 year ago

Entertainment1 year agoRemembering Melanie Olmstead Yellowstone’s Unsung Hero

-

Uncategorized1 year ago

Uncategorized1 year agoPrairie Dog Guide: Habitat, Behavior, and Conservation

-

Celebrity1 year ago

Celebrity1 year agoA Deep Dive into Jeremy Allen White Movies and TV Shows

-

Business1 year ago

Business1 year agoHow Influencersginewuld Shapes the Future of Branding

-

Apps & Games1 year ago

Apps & Games1 year agoThe Pizza Edition Games: A Perfect Slice of Fun and Flavor